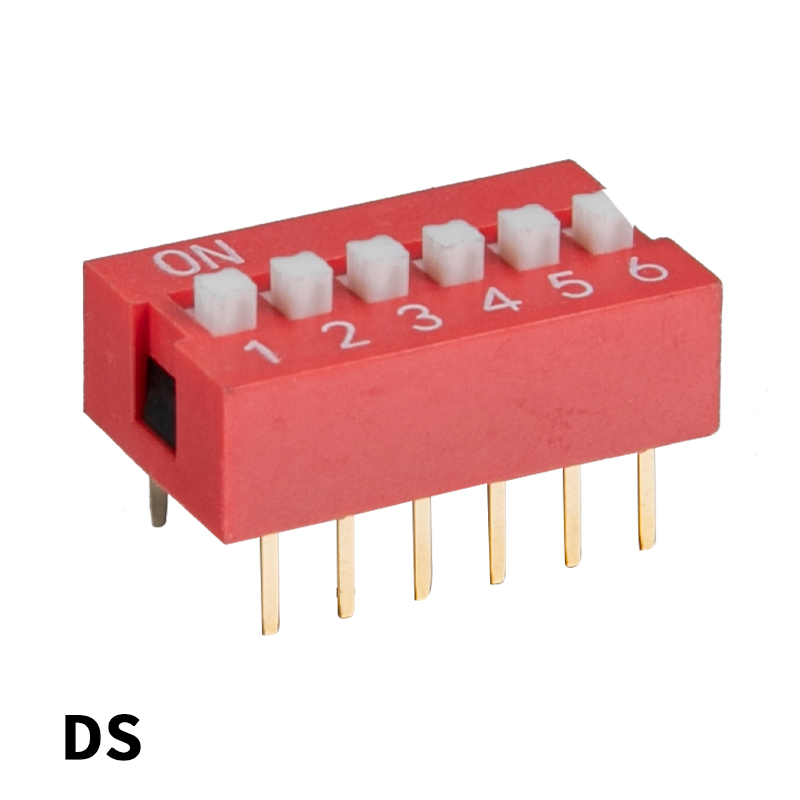

What are DIP switches? A DIP switch is an electronic switch that is packed together with other devices in a single unit in a typical dual in line package. The word DIP often refers to both the switch itself, and to the device in the package as a whole called a discrete interference insert. The switch has two pins that can be pulled up and pushed down to regulate the power supplied to the device.

There are four different types of DIP switches. The most popular and versatile is the standard circuit interconnect (PCI). Standard circuit interconnects are DIP like but have a standard PCB that contains all the wires for the connection. The DIP style of switch only allows one wire to be attached per slot, along with an IDC connector. The most common use for standard circuit interconnects is a PC style computer model where several different models are installed in a single system.

Nbmax Low profile dip switches are DIP switches that feature two low-cost components instead of the three necessary components provided by a standard switch. The low-profile DIP makes it possible to install the device in areas where standard DIP would be impossible to install such as in a tight space. Another of the low profile dip switches is the rotary screw DIP. The rotary screw DIP has one jack and one screw, making it difficult to remove the main power supply unless the jack and screw are removed from the mounting sleeve and the switch is disconnected.

Pins that are DIP compatible are typically made of gold, tantalized aluminum or some other metal. However, DIP type components are commonly used in applications where the component will be installed in an environment where the life span of the component is an important factor. These include automotive, home electronics, medical and communications applications.

The benefits of DIP Switches are that they provide a cost-effective way to control the input signal to a device. They are easy to install with minimal physical work and they can be programmed to control several devices at the same time. Another benefit of DIP switches is that they provide a number of options when it comes to configuration. Some of the different configurations include threshold limit, speed control and jumpers. With regards to the threshold limit, a typical DIP switch will control the device when the threshold value reaches a pre-determined level.

A DIP switched device is designed so that there are low conductance electrical contacts between the physical layer and the insulation layer. The physical layer is generally comprised of a thin insulating material, such as an aluminum plate. On the other hand, the insulating layer on the other hand is made from either polyester or a foam like substance. There are four main varieties of DIP switches: magnetic, switching, rocker and pull-down.

For small to medium size indoor and outdoor systems, a DIP Switch can provide the best solution due to its ease of installation and reliability. A DIP Switched device offers two solutions: one is a magnetic type and the other is a switching or rocker type. A DIP Switched device allows you to configure the physical layer to limit the amount of current passing through, and it also allows you to configure the physical layer to limit the amount of thermal radiation that passes through the electrical contacts.

In addition to providing a cost effective and reliable method for controlling the physical layer, DIP Switches is available in surface-mount packages. The advantage to using surface mount switches is that they offer more flexibility and are easier to install. However, while they may be a good choice for some applications, DIP Switches that use surface-mount devices will not be able to offer the same level of configurability and reliability as those that are installed under the enclosures of the enclosure. A DIP Switched device can also be used with surface mount circuit boards, which have an additional benefit of offering a tight fit with the surface of the board. Surface mount switch devices are often used in areas where space is limited and in conjunction with other types of switches such as magnetic and thermal diodes they offer excellent thermal control and reliability.