Key components: PS-ON, precision voltage stabilizing circuit, PWM control chip, push tube (composed of two triodes), drive transformer, main switch transformer Principle: the oscillation circuit is composed of push tube and PWM (Pulse Width Modulation) control chip, When a high-frequency pulse is generated in standby.

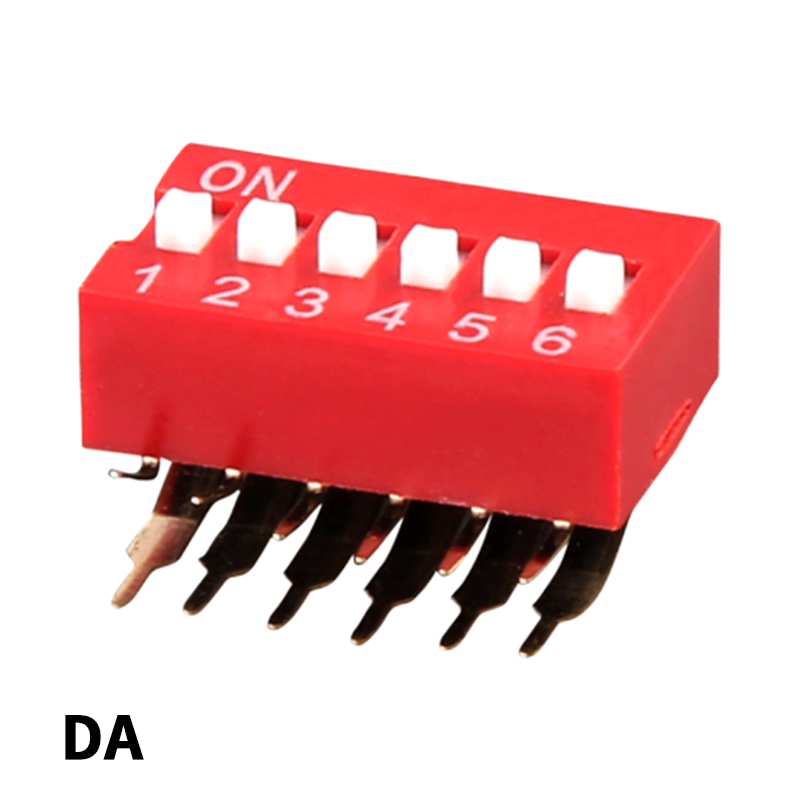

The electronic switch of the main board opening and closing control circuit is disconnected, and the PWM control chip blocks the modulation pulse width output, so that T2 drives the transformer, and the T1 main power switch transformer stops vibration and stops providing output voltage. After the controlled start, the main board open and close electronic switch is grounded. The PWM control chip outputs the pulse width modulation signal and controls the T2 connected to the c pole of Q3 and Q4 to drive the excitation oscillation of the primary winding of the transformer, and the induced potential generated by the excitation oscillation of the KE dip switch T2 acts on the primary power switch transformer of the T1 Winding, the induced potential of the secondary winding is rectified to form an output voltage of +3 3V, ±5V, and ±12V.

Protection circuit-seven protection

1. Input overvoltage protection: varistor with a withstand voltage of 270V

2. Input overcurrent protection: fuse

3. Over-current protection at the output: through wire feedback, the drive transformer will act accordingly to shut off the output of the power supply.

4. Output terminal overvoltage protection: When the output voltage detected by the comparator has a large deviation from the reference voltage, the voltage regulator tube will adjust the voltage.

5. Output overload protection: The mechanism of overload protection is the same as that of overcurrent protection, which is also carried out by the control circuit and the drive transformer.

6. KingTek output short-circuit protection: When the output is short-circuited, the comparator will detect the change in current and turn off the output of the switch tube through the drive transformer and PWM.

7. Temperature control: detect the internal temperature of the power supply through a temperature probe, and intelligently adjust the fan speed to control the internal temperature of the power supply.